240 Series Temperature Monitor

This was the main product I developed in my short tenure at Lake Shore Cryotronics. My job was to create a more cost-effective and simpler temperature monitor geared towards industrial markets, but without sacrificing the standards that Lake Shore is known for. Same great noise performance and high precision, but economical. The idea was to keep the price point closer to that of their patented Cernox cryogenic temperature sensors, so a customer could buy 20 Cernox sensors for their liquid hydrogen system and a couple of these and seamlessly integrate them into their SCADA system. I did all the circuit design and architecture, implementing new features the company had never tried, up through the prototype phase. I left Lake Shore in 2022, leaving this in limbo for a bit until someone could pick it back up, and evaluation kits for this product are available as of summer 2024.

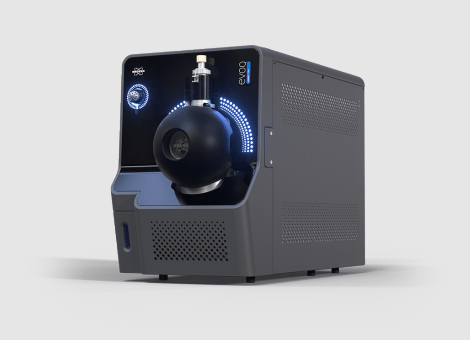

This is Bruker’s triple quadrature mass spectrometer. Many mass specs use a quadrature pole system of some kind as a filter somewhere in the process, and the triple quad team is the one doing all the R&D on the quads, so any improvements here ripple down to all the other mass specs using it. There are three varieties, gas chromatography, liquid chromatography, and DART. The main R&D team was in Germany and Switzerland, I was on the applied markets team in the US headquarters working on things like integrating the DART into the EVOQ, creating a new autosampler, troubleshooting and updating various subsystems, and redoing the aesthetic design (like fun LED circuits on the front panel!).

DART (Direct Analysis in Real Time) Mass Spectrometry

Bruker purchased a company called IonSense. Normally in mass spectrometry you take a sample and then put it through some kind of process that separates the various chemicals to make it easier to identify things, like liquid or gas chromatography. This system allows you put the sample as-is directly in front of the “gun”, which shoots blasts of hot ionized helium and shoots the sample into the mass spec, and get a quick accurate reading in a matter of seconds. My job was to take that blue box, deconstruct and strip the unnecessary stuff, and redesign the circuitry into an existing mass spec so the gun alone could act as a native attachment. Lots of interesting problems here, high voltages, high temperatures, ionized helium, automation control and so on.

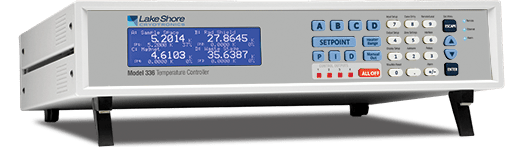

Lake Shore and Janis Research were all about controlling temperature, and the 336 was the gold standard for that. These platforms are remarkable systems of temperature measurement and control, keeping dilution fridges and cryostats down in the 3-10K range. Thanks to COVID and a series of fires at Renesas’s warehouses (no seriously), the ADCs at the heart of this instrument were going to be out of stock for years. That ADC was very unique and the whole analog front-end was designed around it, so it became my job to revamp the entire signal chain while meeting/exceeding the existing specs. This also gave us an opportunity to update some other parts of the circuitry and implement firmware features for robustness.

I got hired on to Lake Shore’s product development team to help out with this effort and there’s been a lot of great work done here. This system is meant to do it all, sourcing and measuring current, DC and AC and even lock-in measurements. The main competitors are instruments like the Keithley 6220 and 2182a Delta combo that can take low level low noise DC measurements, as well as the SRS830 Lock In Amplifier.

The instrument was in its late stage when I joined so my job was helping bring it from prototype to finished product.

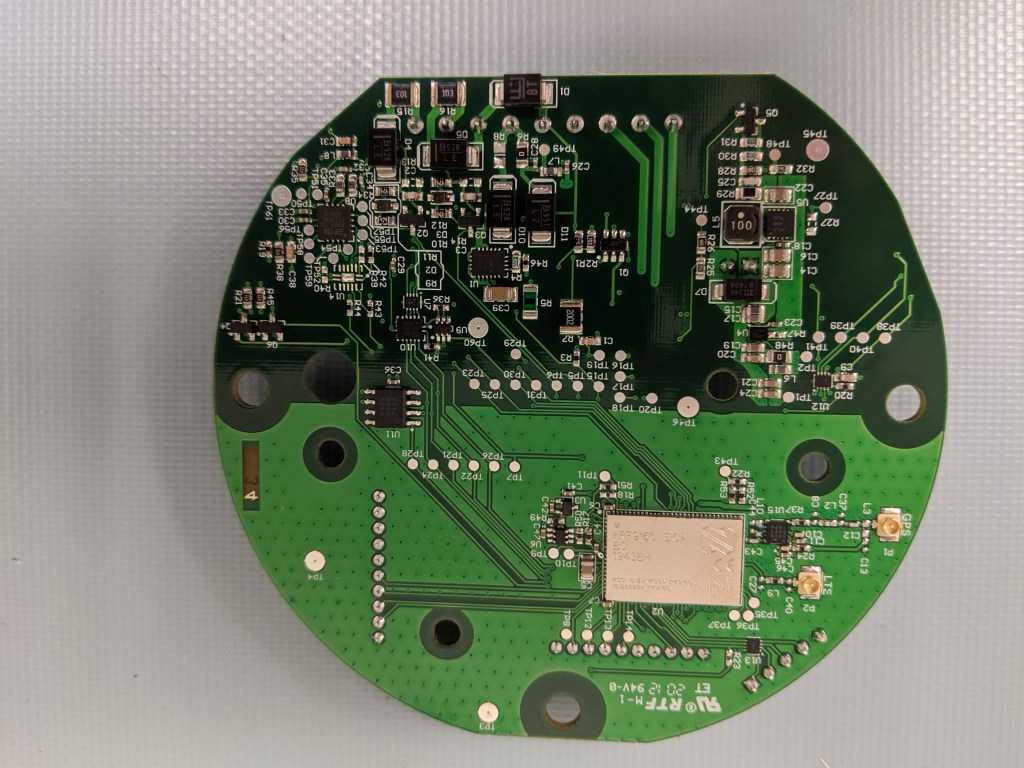

This was the next major step for SignalFire, and looking back on it, for IoT in general. Up until now everything they did was 900MHz ISM band, but they’ve now made the move into LTE-M1 IoT. I did all the hardware design except for the RF portion, all testing and certifications including getting it tested with the ISP. In fact, we were literally the 5th product testing AT&T’s LTE-M1 IoT service, so I was communicating a lot with AT&T’s engineers and helping them beta test and debug their infrastructure. I also did all the documentation, supported customer training, and went on sales calls as the resident nerd.

This product was such a massive success that people called in asking for a variety of configurations integrating this with our other products. I developed a few turn-key solutions for that which it looks like they’ve since turned into full-fledged systems of their own. Out of anything I’ve worked on, this is easily the most successful and most sold by a wide margin.

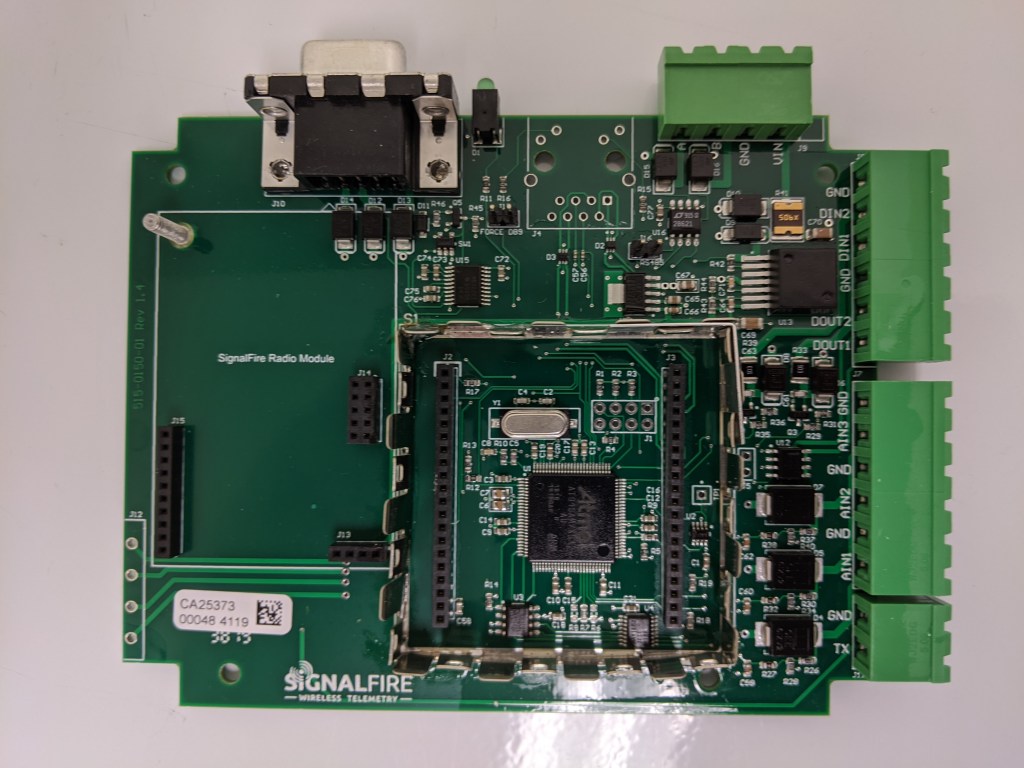

This was the first major product I developed myself start to finish. SignalFire’s 900MHz radios all communicate back to a Gateway that makes the data available to a PLC/RTU/SCADA over Modbus. The DIN Gateway V2 was meant to connect two different modules. Gateways communicate over Modbus RTU by default, or Modbus TCP with an attachment. The DIN Gateway V2 combined the ethernet interface with the main Gateway, and provided extra on-board I/O.

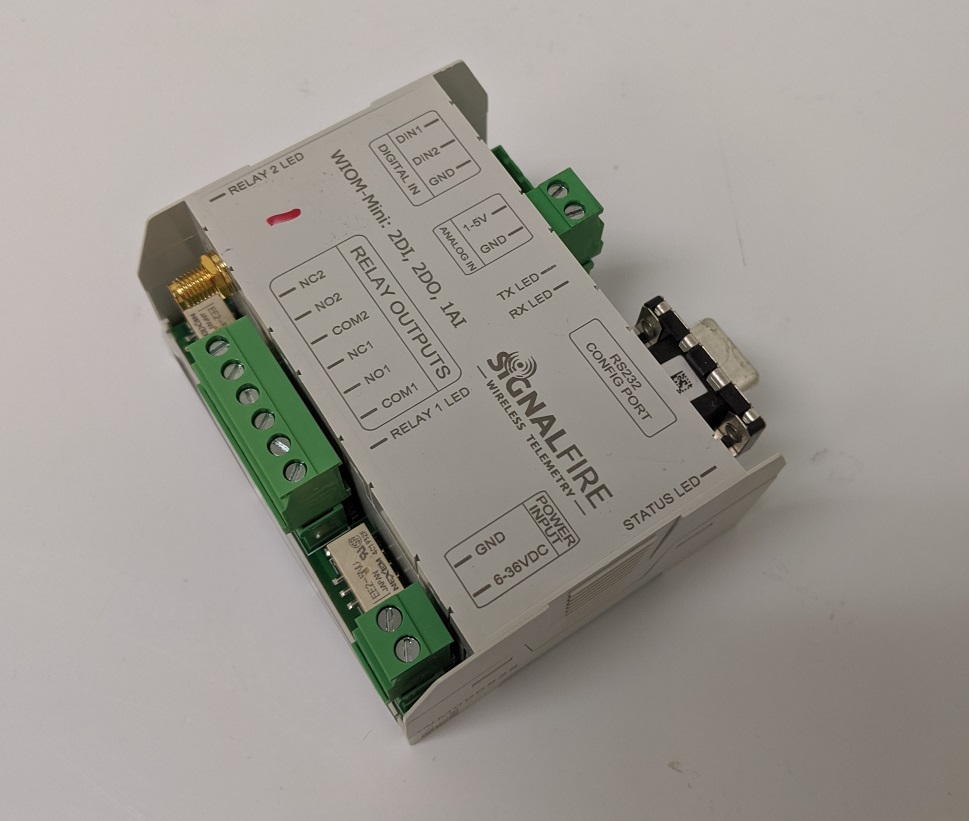

As the name suggests, it’s the miniature version of the Wireless I/O Module. The original had too much I/O for a lot of applications, so the price wasn’t justified. The WIOM-Mini now outsells the original WIOM. I took this product from start to finish, including concept, schematic, PCB layout, mechanical enclosure and labeling, and certifications.

Fairly simple I/O expansion module for the Gateway. It’s basically just an array of MOSFETs and protections. Meant to accompany the aptly named Analog Output Module.

TILDAS – Quantum Cascade Laser trace gas detection system

These things were a beauty. I built, calibrated, and tested these optical systems used by climate/atmospheric scientists that could detect NO2 down to a precision of 30 parts per trillion. Each unit was a months long process. I certainly didn’t develop these, but my job was IT management for the computer systems and managing the dozens of cables and connectors. Down the road I helped develop boards for additional features, like a solenoid controller for a valve system, and a temperature sense and control system for the optical cell to increase the precision.